Reach Out to Print House Printing Press Now!

Binding and finishing are crucial steps in the printing process that give printed materials their final polished look and functionality. In a print house printing press, these processes are where the magic happens after the ink meets paper. Let’s delve into the world of binding and finishing to understand their significance and various techniques.

Binding

Binding refers to the methods used to assemble printed pages into a finished product. It’s not just about putting pages together but also ensuring durability, functionality, and aesthetics. Print houses employ different binding techniques based on the type of printed materials and their intended use.

Perfect Binding: This method is commonly used for books, magazines, and catalogs. Pages are glued together along the spine, creating a clean and professional look. Perfect binding is cost-effective and suitable for medium to large page counts.

Saddle Stitching: Ideal for booklets, brochures, and newsletters with fewer pages, saddle stitching involves folding sheets and stapling them along the spine. It’s a quick and economical binding method for smaller publications.

Spiral Binding: Also known as coil binding, this method uses a plastic or metal coil threaded through holes punched along the edge of the pages. Spiral binding allows the pages to lay flat and is popular for notebooks, manuals, and presentations.

Wire-O Binding: Similar to spiral binding but using a double-loop wire instead of a coil, Wire-O binding provides a more professional appearance and is often used for calendars, manuals, and reference books.

Case Binding: Reserved for hardcover books, case binding involves attaching a cover to the book block using adhesive. It adds durability and a premium feel, making it suitable for special editions and high-end publications.

Finishing

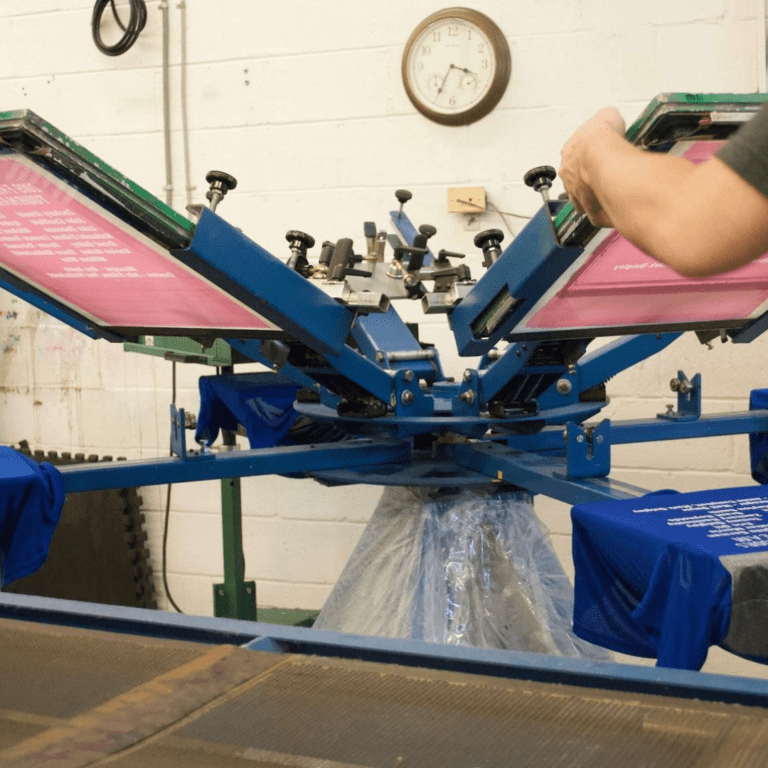

Finishing encompasses a range of processes that enhance the appearance and functionality of printed materials. It adds value and appeal to the final product, making it more engaging for the audience. Some common finishing techniques include:

Laminating: Applying a thin layer of plastic film to printed materials for protection against wear, tear, and moisture. Laminating can be glossy or matte, enhancing both aesthetics and durability.

Embossing/Debossing: Creating raised or recessed designs on paper using heat and pressure. This technique adds texture and visual interest, making logos, titles, and graphics stand out.

Foil Stamping: Adding metallic or colored foil to specific areas of printed materials using heat and pressure. Foil stamping creates a luxurious and eye-catching effect, often used for branding elements and decorative accents.

UV Coating: Applying a glossy or matte coating to printed surfaces for added protection and a professional finish. UV coating enhances colors and contrasts while improving durability.

Die-Cutting: Using a die to cut printed materials into custom shapes and designs. Die-cutting adds creativity and uniqueness to products like business cards, invitations, and packaging.

In a print house printing press, the combination of precise binding techniques and creative finishing touches transforms ordinary prints into exceptional pieces that captivate and impress audiences. These processes not only contribute to the aesthetics but also ensure that printed materials are functional, durable, and aligned with the client’s vision.

Print House Printing Press is a beacon of print excellence, offering diverse solutions with cutting-edge technology. Their client-centric approach, skilled team, and sustainability commitment ensure unparalleled quality and innovation in every project.

Navigation Links

Our Services

Contact Us

- info@printhouseqa.com

- +974 44150299

- Building No: 74, Street No: 3144, Birkat Al Awamer, Qatar

-

Saturday - Thursday

7:30 AM to 4:00 PM

© Copyright 2024 | Print House Printing Press. All Rights & Reserved